At present, in high-rise buildings, to handle the problem of excessive water pressure and flow rate at lower floors; PRVs (Pressure Reducing Valve) are being installed at every entry point, from where water connection enters into a dwelling unit (water connection – entry point). Generally, in a dwelling unit, number of these entry points is equal to the number of bathrooms.

But from practice, it has been observed that in a dwelling unit, even installation of PRV at every entry point; does not solve following problems.

- Availability of excessive flow rate at downstream of all taps (water outlet); because a PRV, installed at an entry point results in reducing of static pressure to a desired level (a part of total pressure), only and not in reducing of total pressure.

- Un-equal water distribution at downstream of water taps; whenever, two or more water taps are being used for water collection, simultaneously.

From practice, it has also been observed that in buildings of a hill area; none of the water management device is being used because; PRV is a costly device (with frequent repair requirements and limited useful life). Also, in hill areas, most of the people are of weaker financial status living at below the poverty line i.e. at the base of pyramid.

Present device, kills the total water pressure and the associated flow rate, in almost equal proportions, simultaneously. This device needs to be installed at the back of every tap (or any other water outlet like shower etc.).

As this device, kills the total water pressure and associated flow rate, simultaneously; it solves both above problems, which are being faced by the consumers using PRVs.

Present device, is much cheaper economic than a PRV; therefore can easily be used by users living in a hill areas too, besides people living in other areas. Present device has potential to save 20-30% of water and thus in savings of equal amount in water bills and cost of electricity (used for pumping of water).

From practice, it has been observed that a flow rate of about 6-8 liter/minute is sufficient enough to meet all domestic requirements of a consumer.

Present device can be designed to deliver a flow rate of 6-8 liter/minute or more at a given inlet pleasure of 2 kg/cm2 or more.

Meaning thereby, a tailor made solution is available in the form of our device i.e. A Pressure and Flow Control Valve (PFCV).

In India or in global market, to manage pressure and flow rate of a flowing fluid; pressure reducing valves (PRVs) and flow control valves (FCVs), respectively, are available. But, at present, no device/valve is available, which can regulate pressure and flow rate of a flowing fluid, simultaneously. This makes, this technology, unique from any other existing technology, device/valve.

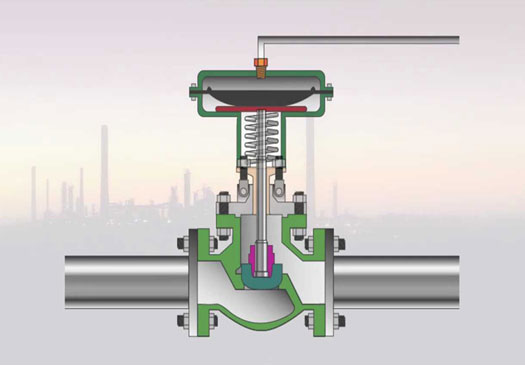

Pressure Reducing Valve (PRV):

A PRV helps in maintaining a pre-determined pressure at upstream of a pressure sensitive device during flow and no-flow conditions.

PRVs are built to minimize dynamic pressure drop from their set pressure, so as to give maximum possible flow. PRV is not a safety valve but a working control; and as it is required to work all the time, it will have a finite life expectancy.

A PRV does not help in regulating/managing flow rate of a flowing fluid.