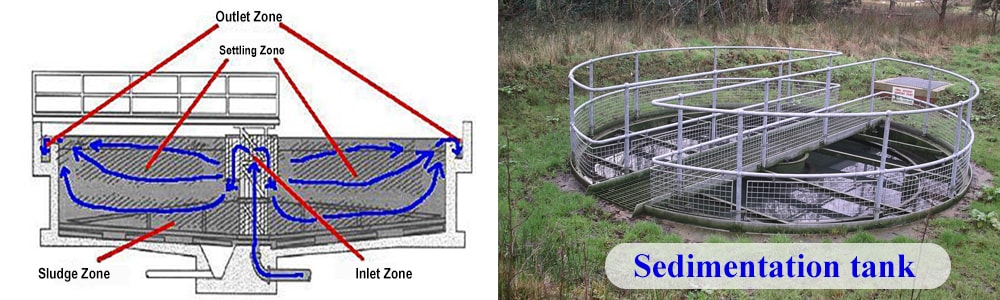

In a water treatment plant (WTP), sedimentation tank is a very important part. Herein, suspended impurities, present in raw water, are allowed to get settled at its base; from where, in due course of time, these impurities are being removed for final disposal.

As settling of suspended impurities consume sufficiently longer time; thus, this activity decides, over all area of land required for setting up of a water treatment plant and also the total time required to complete entire water treatment process.

This process is absolutely necessary/ important because if these impurities are not removed here effectively (in a sedimentation tank), then these impurities will increase the required dose of alum or other chemicals at the time of coagulation process (an activity, wherein colloidal/dissolved impurities are being removed from partially cleaned water).

In a sedimentation tank, to attain calm conditions; and also to achieve early settling of suspended impurities, we allow raw water to enter, and flow, at a slower speed.

Presently, barriers are being created in the flow/travel path of water.

Present device has potential to kill pressure and flow rate of a flowing fluid i.e. water and thus will help in attaining calm conditions in a much shorter time period than existing current practices. Also, this activity would result in cut short of residence time of raw water in a sedimentation tank; thus this device would help in completing water treatment process faster; and also in reducing required land area for setting up of a water treatment plant.

For that purpose, present device of required sizes are needed to be installed across the flowing path of raw water.

Note: In a sewerage treatment plant (STP), incoming effluent requires similar treatment to remove silt. Present device is equally suitable to serve that purpose, too.